Your customized Xbox controller is more intricate than you think; I had a conversation with the person who created it.

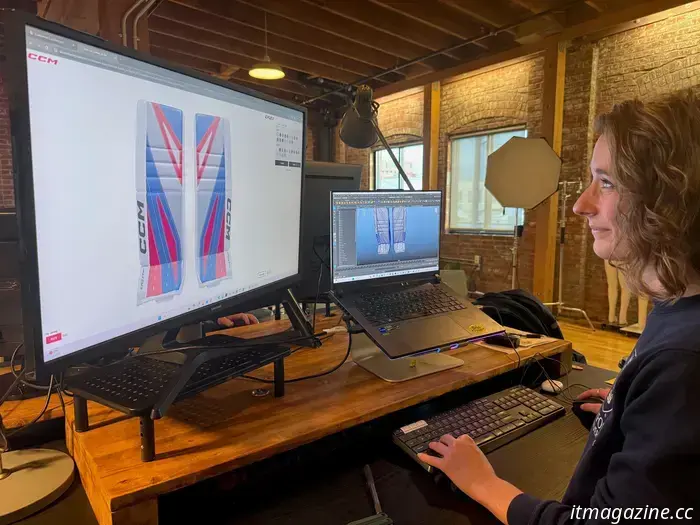

In a time when individuality is a form of social currency more precious than gold, digital customization is revolutionizing consumer products, ranging from gaming controllers to daily clothing. Co-founded by Levi Patterson, Spectrum, located in Portland, has developed an advanced 3D-to-factory platform that facilitates personalized designs for prominent brands such as Xbox, Carhartt, and Hydro Flask.

Levi also co-founded the marketing agency Pollinate, where he leverages his knowledge to enhance strategic integrations that transform user interaction with custom items.

In a discussion with Digital Trends, Mr. Patterson shares insights on the engineering breakthroughs that allow for realistic product previews, the challenges of scaling these systems globally, and the future of engaging, tailored experiences in gaming and other areas.

Digital Trends (DT): As one of the founders at Spectrum since 2011, what ignited your interest in 3D product customization, and how has your marketing experience from co-founding Pollinate shaped the platform’s emphasis on seamless consumer experiences like Xbox Design Lab? What obstacles do companies encounter when incorporating 3D visualization tools, like those used in Xbox Design Lab’s real-time previews, into e-commerce, and how does this affect the experience for casual vs. hardcore customizers?

Levi Patterson (LP): My decade-long experience in digital marketing prior to launching Spectrum provided us with valuable insights into our priorities. It quickly became clear that “what you see is what you get” (WYSIWYG) is a fundamental expectation among customers. Consequently, we recognized the necessity to develop 3D visualization, which ultimately evolved into 3DTrue, focusing on accurately representing customer creations in 3D. Our commitment to our clients and their users is to ensure that what’s designed on-screen aligns with what arrives in the package. Thankfully, this expectation is consistent among both casual and hardcore users, prompting us to prioritize premium visualization as our default. While this has been a challenge, we have continually adapted and progressed.

DT: Spectrum boasts a 100% factory integration rate across various brands. Can you describe a significant “aha” moment early on that convinced you this technology could bridge the digital design and real-world manufacturing gap?

LP: Unlike many configuration solutions that concentrate on the front end, we invest substantial time in factories and embellishment facilities aligning digital designs with reality for automated file delivery. Initially, we worried that we had taken on too much, but witnessing our first fully sublimated garment come off the production line was a defining moment, affirming that we had something remarkable. Attention to detail is crucial, and we've successfully codified those details into our platform.

DT: Spectrum's data indicates a 72% reduction in 3D load speeds and a 63% decrease in resource sizes. How did your team prioritize these improvements for crucial applications like Xbox Design Lab, and what does this mean for gamers adjusting designs on mobile devices?

LP: Our team at Spectrum has dedicated years to fine-tuning our 3D asset pipeline to ensure optimization at every stage. Beginning with the models, we take the provided CAD files, reconstruct only the visible components, and aim for clean, quadrangulated topology to facilitate straightforward texture assignment. The team's focus on weight, map counts, size, and device detection all enhance swift, interactive experiences across desktop and mobile platforms. These memory optimizations support more real-time features—like translucency, sheens, lightmaps, and intricate animations—allowing us to expand the limits of what can be done while sustaining sustainable frame rates.

DT: With precise material rendering for everything from controller plastics to Carhartt fabrics, how does Spectrum tackle the challenges of simulating textures such as leather or metal in real-time, and might this evolve to facilitate AR try-ons for custom gaming peripherals?

LP: Our PBR approach, combined with the scanning technologies we've embraced over the years, leads to the creation of highly authentic materials. To accurately replicate existing products in 3D, we also receive samples to observe how the surface interacts with light. Moreover, all assets are constructed to real-world scale, making it easy to transition into an AR environment using supported formats.

DT: Features like roster/group orders and artwork re-coloring seem transformative for teams or esports squads. Could you highlight one lesser-known tool in Spectrum’s toolkit that has changed how brands like JBL or Leatherman engage their communities?

LP: Moderation comes to mind as a crucial feature since protecting the brand is vital. We aim to provide users with a platform for their creativity while maintaining boundaries. We've been employing AI for this purpose long before ChatGPT gained mainstream attention, analyzing images in real-time to detect inappropriate content, copyright infringement, or prohibited terms and phrases.

DT: Drawing from successes like Life is Good Custom and Hydro Flask's personalization, what insights have you applied from apparel and drinkware to gaming gear, and how might Spectrum expand into custom VR headsets or modular console skins?

LP: We can now visualize nearly anything on any product

Other articles

If the PS6 does incorporate a handheld, Sony has the opportunity to draw inspiration from various sources this time around.

Sony can gain insights not only from the Vita but also from its competitors.

If the PS6 does incorporate a handheld, Sony has the opportunity to draw inspiration from various sources this time around.

Sony can gain insights not only from the Vita but also from its competitors.

The Exynos 2600 may offer enhanced on-device AI performance for the Galaxy S26 series.

Samsung is said to have teamed up with Nota AI to improve the on-device AI features of the Exynos 2600.

The Exynos 2600 may offer enhanced on-device AI performance for the Galaxy S26 series.

Samsung is said to have teamed up with Nota AI to improve the on-device AI features of the Exynos 2600.

Digital Trends may receive a commission if you make a purchase through links on our website. Why trust us?

Save $1,000 on the Legion Pro 7i, a 240Hz OLED powerhouse designed for high FPS gaming.

Best Buy

If you’ve been keeping an eye on high-end gaming laptops and waiting for a significant discount, this is one of those rare price reductions that truly matters. The Lenovo Legion Pro 7i, featuring a 16-inch WQXGA OLED 240Hz display, Intel Core Ultra 9 275HX, RTX 5090, 32GB RAM, and a 1TB SSD, has dropped to $2,999.99 (from $3,999.99), providing a savings of $1,000.

While it’s still a premium investment, it represents a more accessible entry point for a “no compromises” laptop designed to deliver high frame rates in modern games while also looking impressive.

What you’re getting

This gaming laptop features a 16-inch, non-touch display running at a resolution of 2560 x 1600 with a 240Hz refresh rate, accompanied by an RTX 5090 and 32GB of memory. In practical terms, you benefit from a sharp image and ample workspace provided by the 16:10 resolution, the smoothness competitive gamers prioritize, and the GPU capacity to run demanding titles or maximize settings while maintaining high frame rates.

It's also designed with performance in mind, featuring robust cooling, catering to those who value sustained power over merely thin specifications.

Why it’s worth it

This deal is appealing because it addresses two crucial aspects that enthusiasts notice immediately: the screen quality and the GPU. An OLED display with a high refresh rate enhances the overall experience, from darker scenes in games to improved motion clarity in shooters. The RTX 5090 GPU is ideal for those looking to keep the laptop for years, play at higher settings, or connect to an external display later.

The discount makes the weight and bulk of a larger laptop more justifiable. Laptops in this category are designed to handle heat and power, which often results in increased weight, more fan noise under heavy use, and less unplugged gaming time compared to slimmer models. If you intend to use it as a portable desktop replacement, these compromises are typically worth it.

The bottom line

At $2,999.99, the Legion Pro 7i is an excellent purchase for anyone seeking top-tier gaming performance and a premium high-refresh OLED display, especially if you've been waiting for a significant discount. However, if you primarily engage in esports titles at lower settings or prioritize portability over power, you can find more affordable options that will still satisfy your needs.

I'm a writer, entrepreneur, and powerlifting coach. I’ve been assembling computers and experimenting with PC components for many years…

AFEELA introduces PS Remote Play, allowing you to play your PlayStation 5 while parked.

The feature streams games from your home console to AFEELA's cabin display, but SHM advises that a strong and stable broadband connection is recommended.

Sony Honda Mobility (SHM) has announced that AFEELA will incorporate AFEELA PS Remote Play, letting you stream games from a PS5 or PS4 at home to the car’s built-in interface. SHM claims it is the first vehicle to seamlessly integrate PlayStation Remote Play into its infotainment system.

It’s an appealing feature for those who have spent time in a parking lot or waited in long pickup lines. SHM suggests the purpose is to enable gaming while the car is stationary or to entertain passengers during longer trips, utilizing the cabin display and audio instead of a separate screen.

Read more

Steam Deck LCD is being phased out; here’s what it means for your next handheld purchase.

Valve has announced it will discontinue the Steam Deck LCD 256GB configuration, which will no longer be available once current stock is depleted.

Valve has decided to end sales of the Steam Deck LCD for one of its main configurations. According to the Steam Deck store page, Valve stated that it is "phasing out the Steam Deck LCD 256GB model" and that it "will no longer be available" once the remaining inventory runs out.

The announcement also clarifies that sales are distinct from support. Valve assures users that it will "continue to provide support for Steam Deck LCD on an ongoing basis," alleviating concerns for those who already possess an LCD model.

Read more

GeForce NOW’s 100-hour cap explained for your monthly playtime.

For light usage, it may not feel different, but for more extensive gaming sessions, understanding the cap and add-on options is important.

GeForce NOW will implement the 100-hour cap starting January 1, introducing a monthly playtime limit that could impact how some subscribers manage their gaming time. The primary question is whether this cap will affect you immediately or if you will still have considerable time left.

A Reddit user has already attempted to

The latest update from WhatsApp introduces four new features designed to help you share New Year’s joy.

Digital Trends may receive a commission if you make a purchase through links on our website. Why trust us?

Save $1,000 on the Legion Pro 7i, a 240Hz OLED powerhouse designed for high FPS gaming.

Best Buy

If you’ve been keeping an eye on high-end gaming laptops and waiting for a significant discount, this is one of those rare price reductions that truly matters. The Lenovo Legion Pro 7i, featuring a 16-inch WQXGA OLED 240Hz display, Intel Core Ultra 9 275HX, RTX 5090, 32GB RAM, and a 1TB SSD, has dropped to $2,999.99 (from $3,999.99), providing a savings of $1,000.

While it’s still a premium investment, it represents a more accessible entry point for a “no compromises” laptop designed to deliver high frame rates in modern games while also looking impressive.

What you’re getting

This gaming laptop features a 16-inch, non-touch display running at a resolution of 2560 x 1600 with a 240Hz refresh rate, accompanied by an RTX 5090 and 32GB of memory. In practical terms, you benefit from a sharp image and ample workspace provided by the 16:10 resolution, the smoothness competitive gamers prioritize, and the GPU capacity to run demanding titles or maximize settings while maintaining high frame rates.

It's also designed with performance in mind, featuring robust cooling, catering to those who value sustained power over merely thin specifications.

Why it’s worth it

This deal is appealing because it addresses two crucial aspects that enthusiasts notice immediately: the screen quality and the GPU. An OLED display with a high refresh rate enhances the overall experience, from darker scenes in games to improved motion clarity in shooters. The RTX 5090 GPU is ideal for those looking to keep the laptop for years, play at higher settings, or connect to an external display later.

The discount makes the weight and bulk of a larger laptop more justifiable. Laptops in this category are designed to handle heat and power, which often results in increased weight, more fan noise under heavy use, and less unplugged gaming time compared to slimmer models. If you intend to use it as a portable desktop replacement, these compromises are typically worth it.

The bottom line

At $2,999.99, the Legion Pro 7i is an excellent purchase for anyone seeking top-tier gaming performance and a premium high-refresh OLED display, especially if you've been waiting for a significant discount. However, if you primarily engage in esports titles at lower settings or prioritize portability over power, you can find more affordable options that will still satisfy your needs.

I'm a writer, entrepreneur, and powerlifting coach. I’ve been assembling computers and experimenting with PC components for many years…

AFEELA introduces PS Remote Play, allowing you to play your PlayStation 5 while parked.

The feature streams games from your home console to AFEELA's cabin display, but SHM advises that a strong and stable broadband connection is recommended.

Sony Honda Mobility (SHM) has announced that AFEELA will incorporate AFEELA PS Remote Play, letting you stream games from a PS5 or PS4 at home to the car’s built-in interface. SHM claims it is the first vehicle to seamlessly integrate PlayStation Remote Play into its infotainment system.

It’s an appealing feature for those who have spent time in a parking lot or waited in long pickup lines. SHM suggests the purpose is to enable gaming while the car is stationary or to entertain passengers during longer trips, utilizing the cabin display and audio instead of a separate screen.

Read more

Steam Deck LCD is being phased out; here’s what it means for your next handheld purchase.

Valve has announced it will discontinue the Steam Deck LCD 256GB configuration, which will no longer be available once current stock is depleted.

Valve has decided to end sales of the Steam Deck LCD for one of its main configurations. According to the Steam Deck store page, Valve stated that it is "phasing out the Steam Deck LCD 256GB model" and that it "will no longer be available" once the remaining inventory runs out.

The announcement also clarifies that sales are distinct from support. Valve assures users that it will "continue to provide support for Steam Deck LCD on an ongoing basis," alleviating concerns for those who already possess an LCD model.

Read more

GeForce NOW’s 100-hour cap explained for your monthly playtime.

For light usage, it may not feel different, but for more extensive gaming sessions, understanding the cap and add-on options is important.

GeForce NOW will implement the 100-hour cap starting January 1, introducing a monthly playtime limit that could impact how some subscribers manage their gaming time. The primary question is whether this cap will affect you immediately or if you will still have considerable time left.

A Reddit user has already attempted to

The latest update from WhatsApp introduces four new features designed to help you share New Year’s joy.

A $1,000 discount makes it more justifiable to purchase this RTX 5090 Legion Pro 7i.

If you've been keeping an eye on premium gaming laptops and are looking for a significant discount, this is one of the rare price reductions that makes a difference. The Lenovo Legion Pro 7i model featuring a 16-inch WQXGA OLED 240Hz screen, Intel Core Ultra 9 275HX, RTX 5090, 32GB RAM, and a 1TB SSD is now available for [...]

A $1,000 discount makes it more justifiable to purchase this RTX 5090 Legion Pro 7i.

If you've been keeping an eye on premium gaming laptops and are looking for a significant discount, this is one of the rare price reductions that makes a difference. The Lenovo Legion Pro 7i model featuring a 16-inch WQXGA OLED 240Hz screen, Intel Core Ultra 9 275HX, RTX 5090, 32GB RAM, and a 1TB SSD is now available for [...]

This portable gaming device will enable you to have a large 8-inch display conveniently in your pocket.

The OneXSugar Wallet is a forthcoming gaming handheld that includes an 8.01-inch folding OLED display, designed in a retro clamshell style.

This portable gaming device will enable you to have a large 8-inch display conveniently in your pocket.

The OneXSugar Wallet is a forthcoming gaming handheld that includes an 8.01-inch folding OLED display, designed in a retro clamshell style.

OpenAI is looking to hire an individual to manage unpredictable risks associated with ChatGPT.

OpenAI is offering a competitive salary and equity to recruit a Head of Preparedness responsible for foreseeing and mitigating significant risks associated with ChatGPT as the technology advances.

OpenAI is looking to hire an individual to manage unpredictable risks associated with ChatGPT.

OpenAI is offering a competitive salary and equity to recruit a Head of Preparedness responsible for foreseeing and mitigating significant risks associated with ChatGPT as the technology advances.

Your customized Xbox controller is more intricate than you think; I had a conversation with the person who created it.

Levi Patterson reveals the advanced 3D-to-factory platform he has developed, which allows for customized designs for prominent brands such as Xbox, Carhartt, and Hydro Flask.