This cargo vessel is converting its CO2 emissions into eco-friendly cement.

A massive cargo ship is capturing carbon from its emissions and converting it into cement for use in land-based construction. The technology, created by UK startup Seabound, is marketed as the world's first commercial carbon capture system for vessels. It has been installed on the UBC Cork, a cement carrier owned by Germany’s Hartmann Group.

“These are the systems we plan to deploy across hundreds, and eventually thousands, of ships,” said Alisha Frediksson, Seabound’s CEO and co-founder, in an interview with TNW. “We’re incredibly eager to get them into operation — to collect important data, refine future versions, and most importantly, to demonstrate to the industry that onboard carbon capture is no longer merely a concept.”

Seabound co-founder Alisha Fredriksson (left) alongside fellow co-founder and CTO Roujia Wen. Credit: Seabound

Seabound’s carbon capture system collects the exhaust fumes produced by the vessel's large diesel engines and directs them into a large, high-pressure chamber filled with calcium hydroxide pebbles. The CO2 in the exhaust gas reacts with these pebbles, converting into calcium carbonate — commonly referred to as limestone, which is essential for cement production. This limestone will be stored on board and then offloaded in Norway, where it will be sent to Heidelberg Materials’ cement plant in Brevik. There, it will contribute to the production of more environmentally friendly concrete on an industrial level as part of Heidelberg’s existing carbon capture operation.

Seabound asserts that its system has the capacity to capture up to 95% of CO₂ and 98% of sulfur emissions from a ship's exhaust. Its modular design allows it to be easily added to existing vessels with minimal modifications. This solution offers the shipping industry a means to reduce emissions immediately, although it cannot replace the long-term necessity for cleaner fuels to entirely eliminate diesel usage.

An illustration of Seabound’s container-sized carbon capture unit from a previous pilot test. Credit: Seabound

A move towards cleaner shipping

The shipping industry is responsible for nearly 3% of global emissions and is particularly challenging to decarbonize. Current battery technology is insufficient to power large cargo vessels for long distances. Nuclear propulsion has also been explored but presents risks and remains contentious.

Most specialists concur that alternative, zero-emission fuels such as hydrogen and ammonia are the best prospects. However, these fuels are still in the early stages of development and necessitate the construction of entirely new vessels.

Seabound’s technology, therefore, could serve as a temporary solution to reduce shipping emissions while waiting for more lasting solutions to be developed.

“Alternative fuels for ships will take at least 10 to 20 years to materialize, but we need to begin decarbonizing now,” said Frediksson in a prior conversation with TNW.

Seabound has already tested its technology with shipping companies Hapag-Lloyd and Lomar Shipping. It is now focused on scaling its systems, aiming to capture 100 million tonnes of CO₂ annually by 2040 — which would account for 10% of the shipping industry's total emissions.

This current initiative, its first commercial project, was co-financed by the EU’s Eurostars startup program and supported by the Cyprus Marine and Maritime Institute.

Other articles

Norwegian investment company ventures into the AI boom in the frigid north.

Aker is the most recent company venturing to the far north to take advantage of plentiful green energy and natural cooling for energy-intensive data centres.

Norwegian investment company ventures into the AI boom in the frigid north.

Aker is the most recent company venturing to the far north to take advantage of plentiful green energy and natural cooling for energy-intensive data centres.

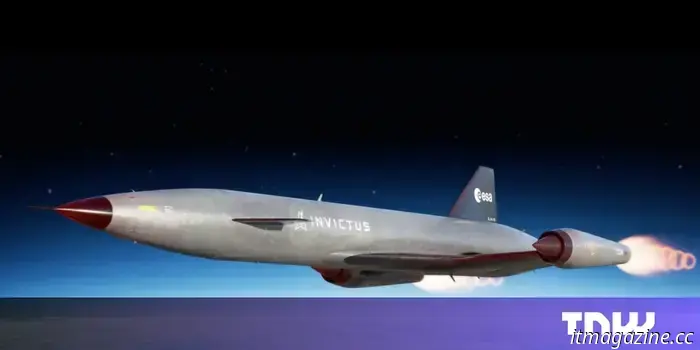

ESA's spaceplane initiative breathes new life into a defunct company's hypersonic engine.

The ESA is supporting a new initiative named Invictus, which seeks to create and launch a hydrogen-fueled spaceplane by 2031.

ESA's spaceplane initiative breathes new life into a defunct company's hypersonic engine.

The ESA is supporting a new initiative named Invictus, which seeks to create and launch a hydrogen-fueled spaceplane by 2031.

Reasons for requesting a pause on the AI Act from the perspective of a climate advocate.

Antoine Rostand, the president and co-founder of the environmental intelligence company Kayrros, is concerned that the AI Act may negatively impact sustainability initiatives.

Reasons for requesting a pause on the AI Act from the perspective of a climate advocate.

Antoine Rostand, the president and co-founder of the environmental intelligence company Kayrros, is concerned that the AI Act may negatively impact sustainability initiatives.

How WeTransfer sparked concerns regarding the training of AI on user data.

WeTransfer users were worried that the company planned to use their data to train AI models. This situation highlighted increasing concerns regarding trust in AI.

How WeTransfer sparked concerns regarding the training of AI on user data.

WeTransfer users were worried that the company planned to use their data to train AI models. This situation highlighted increasing concerns regarding trust in AI.

This cargo vessel is converting its CO2 emissions into eco-friendly cement.

UK startup Seabound claims to have developed the world’s first commercial carbon capture system designed for cargo ships. This system is currently operational at sea.