The company that produces 3D-printed shoes aims to emulate Apple's approach.

A crucial aspect of the individuals and companies we engage with in Trending Forwards is that they must be doing something innovative, and Syntilay certainly embodies this.

Their ambitious aim is to transform the shoe production industry—not only through the method of manufacturing, which involves 3D printing using extensive data, but also by reimagining the ideation, design, and wearing of shoes.

Syntilay employs advanced foot scanning technology to create a detailed map and measurement of your feet, generating thousands of data points that are used by a 3D printer to construct a shoe that fits you perfectly—at a price comparable to standard Birkenstocks.

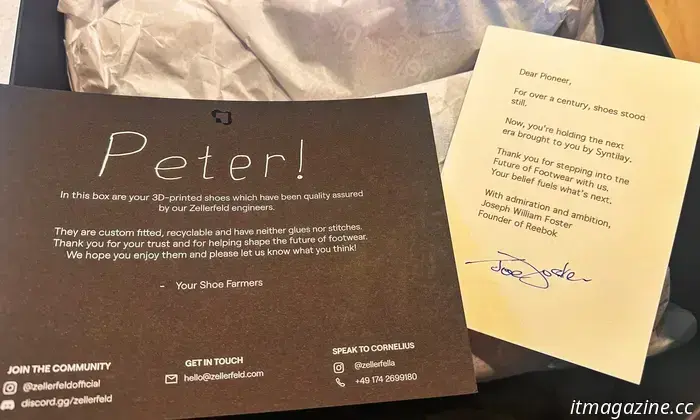

This concept seems groundbreaking, and you can read more about my colleague Peter's experience when he purchased a pair for himself. (Spoiler alert: they are the most comfortable shoes he has ever owned.)

With this in mind, we reached out to Syntilay to invite them to join the Trending Forward series, which explores the future of technology and its various impacts on our lives.

Peter Horan and I spoke with Ben Weiss, Syntilay's CEO, and Joe Foster, the iconic founder of Reebok, who represented the leadership team of this new brand.

During our discussion, we delved into not only the technology behind using AI and 3D printing in footwear production, but also the cultural and fashion dimensions involved in creating highly personalized shoes.

Joe, now 90, has witnessed significant changes in the shoe industry throughout his career, starting with his family’s athletic shoe business in the UK shortly after World War II.

At that time, it was an innovator in athletic shoe production, introducing new manufacturing techniques similar to what Syntilay is pursuing today. Joe and his brother recognized the running boom of the early 1970s, leading them to establish Reebok to seize that opportunity.

Joe mentioned that the "white space" Reebok entered, identifying a demand for mainstream athletic footwear, parallels the opportunity that 3D printed shoes present now.

Syntilay prioritizes being a technology company first.

From the beginning of our discussion, it was evident that Syntilay's mission extends beyond merely creating affordable, custom-fit shoes (although that is an essential element of their business model); they aim to disrupt the industry. They are already collaborating with content creators and influencers to allow for new designs, significantly cutting production costs by 99% in some instances.

Ben stated, “Our question was how to offer content creators their own shoes and brands…an original design from scratch. How can we provide an authentic creative expression that captures the vision of the brand or creator from the start?”

However, the intent to disrupt extends even further—while utilizing advanced technology for shoe production, Ben believes the company will be recognized more for its technological innovations than for the shoes themselves, inspired by the disruptions caused by major tech companies.

Ben explained, “We've seen the impact the Apple Watch has had on the watch industry. It has fundamentally changed how traditional watch companies operate, prompting them to create their own versions.

“But many concepts from the Apple Watch could be applied to footwear. The notion of a single screen with limitless design options is exciting. You can incorporate extensive customization in shoes, and there's much potential there. We also want to provide users with their data, as everyone seems keen to learn more about themselves.”

This vision entails integrating sensors and batteries into the shoes, enabling users to track posture and health metrics, powered by their movement. Imagine 3D printed footwear that connects with your ecosystem of gadgets—potentially even harnessing energy from your activity.

They believe that besides creating personalized shoes, Syntilay can offer customization that surpasses what any other brand can provide. Currently, their sneakers and slides are made from TPU (thermoplastic polyurethane), a highly adaptable elastomer known for its exceptional performance and flexibility.

The company has incorporated additives to give it a softer, foam-like feel rather than a rigid plastic texture. However, they face a significant challenge: production is currently capped at half a million units, compared to the millions that brands like Nike can produce.

Overcoming this limitation will be crucial, as once a design from someone like a UFC fighter or influencer gains traction, it can be mass-produced in the millions.

Our extensive conversation with Ben and Joe also covered various other topics, such as creating a 'leather effect,' allowing customers to hold onto a 3D scan of their feet for repeated use, and their belief in their potential to truly disrupt a multi-billion dollar market.

Be sure to follow Digital Trends on Instagram, YouTube, and TikTok to stay updated on the latest technology and more from Trending Forward as we engage with individuals seeking to leverage tech for world change.

Other articles

This Asus gaming laptop is available for Christmas and has a discount of $500.

If you’re searching for a genuine gaming laptop as a last-minute gift, this is the type of specification list that typically exceeds $1000, even when discounted. With a 165Hz display, the latest RTX 5060, and an unexpectedly ample 32GB of RAM, the TUF F16 appears to be a straightforward, one-time buy for […]

This Asus gaming laptop is available for Christmas and has a discount of $500.

If you’re searching for a genuine gaming laptop as a last-minute gift, this is the type of specification list that typically exceeds $1000, even when discounted. With a 165Hz display, the latest RTX 5060, and an unexpectedly ample 32GB of RAM, the TUF F16 appears to be a straightforward, one-time buy for […]

Microsoft's latest update reveals the reasons why your Windows SSD might not be performing at its best.

Windows 11 users can enhance NVMe SSD performance by utilizing a concealed Microsoft driver, provided they are ready to make some adjustments.

Microsoft's latest update reveals the reasons why your Windows SSD might not be performing at its best.

Windows 11 users can enhance NVMe SSD performance by utilizing a concealed Microsoft driver, provided they are ready to make some adjustments.

Take advantage of a $972 discount on this Samsung bespoke smart refrigerator before the offer disappears.

A 30-cubic-foot French door smart refrigerator priced under $1,500 is rare, particularly from Samsung's Bespoke series. This model is now available for $1,457.99, reduced from $2,429.99, which makes it much more justifiable if you've been delaying a significant kitchen renovation. You’ll enjoy ample space along with a more upscale design compared to standard stainless steel, […]

Take advantage of a $972 discount on this Samsung bespoke smart refrigerator before the offer disappears.

A 30-cubic-foot French door smart refrigerator priced under $1,500 is rare, particularly from Samsung's Bespoke series. This model is now available for $1,457.99, reduced from $2,429.99, which makes it much more justifiable if you've been delaying a significant kitchen renovation. You’ll enjoy ample space along with a more upscale design compared to standard stainless steel, […]

SpaceX is preparing for the last rocket launch of its impressive year.

By various standards, 2025 has been an extraordinary year for SpaceX. The American aerospace company is set to conclude the year with an unprecedented total of 165 launches utilizing its reliable Falcon 9 rocket, with the last launch scheduled for Saturday, December 27. SpaceX's final mission of 2025 will be the COSMO-SkyMed Second Generation project for Italy.

SpaceX is preparing for the last rocket launch of its impressive year.

By various standards, 2025 has been an extraordinary year for SpaceX. The American aerospace company is set to conclude the year with an unprecedented total of 165 launches utilizing its reliable Falcon 9 rocket, with the last launch scheduled for Saturday, December 27. SpaceX's final mission of 2025 will be the COSMO-SkyMed Second Generation project for Italy.

LG’s latest OLED panel merges LCD-level clarity with a 240Hz refresh rate.

LG Display's latest 27-inch 4K OLED panel features a 240Hz refresh rate and an authentic RGB stripe configuration, which could solve the text clarity challenges that have hindered OLED monitors.

LG’s latest OLED panel merges LCD-level clarity with a 240Hz refresh rate.

LG Display's latest 27-inch 4K OLED panel features a 240Hz refresh rate and an authentic RGB stripe configuration, which could solve the text clarity challenges that have hindered OLED monitors.

Lenovo leaks reveal an impressively designed laptop featuring a concealed display beneath a transparent lid.

Lenovo leaks reveal an impressively designed laptop featuring a concealed display beneath a transparent lid.

Lenovo leaks reveal an impressively designed laptop featuring a concealed display beneath a transparent lid.

Lenovo leaks reveal an impressively designed laptop featuring a concealed display beneath a transparent lid.

The company that produces 3D-printed shoes aims to emulate Apple's approach.

Could influencers be crucial in the success of 3D printed footwear?