Forget about 3D printing – these devices can create much more at home.

This article is presented in collaboration with Makera through a paid partnership.

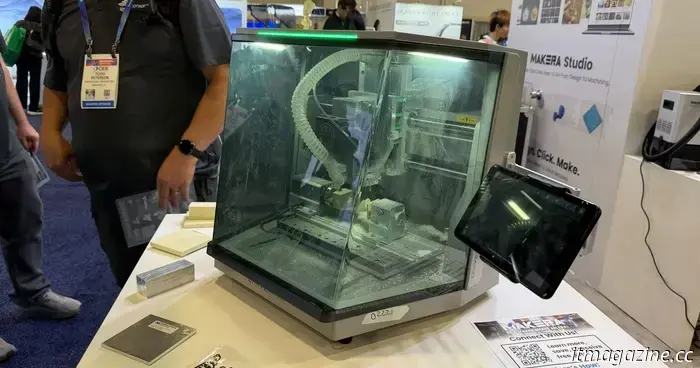

Many individuals may not be familiar with CNC machining; they might only recognize the machines produced by Makera as smaller versions of those used in shop class during their youth, which is indeed accurate.

Makera offers a diverse range of machines: the Makera Carvera, priced at approximately $5000, the Carvera Air, available for about $2000, and the newly launched K1 currently seeking funding on Kickstarter for $979.

If you're unfamiliar with at-home CNC machining, you are missing out on a dynamic community of DIY enthusiasts using these machines to create nearly anything they desire from various materials.

“Right now is an exciting time to be a maker,” stated Jason Erdreich, Education Director at Makera, in an interview with Digital Trends. “Making is trendy, and DIY is thriving.

“We are at a wonderful juncture where, thanks to 3D printing, people are engaging in projects at home. They are building, creating, buying lasers, and starting their own Etsy shops, which is becoming more commonplace.”

Erdreich notes that there is a growing interest among people to advance their creative skills, contributing to the increased demand for Makera's products.

“If you’re someone thinking, ‘I want to create, but I want to work with metal, how do I do that?’ you’ll likely search for DIY metalworking at home and find us among your options.

“The current environment for making and creating is very strong, spanning the DIY sector, education, STEM, robotics, and computer science globally… it has shown consistent growth over the last 10-15 years.

“People are encountering these subjects in educational settings, leading them to pursue projects at home and seek a suitable, compatible system.”

Expanding your learning

Digital Trends

The capabilities of these machines are impressive—they can quickly mold items from materials such as wood or soft metals like brass or copper and can even create printed circuit boards. The Carvera, Makera's first machine, features tools that appeal to professionals, including an automatic tool changer, built-in dust collection, and impressive precision of five micrometers.

The Carvera Air includes a user-friendly quick tool changer, allowing anyone to easily modify the machine's functions, and boasts a cutting precision of 10 microns with closed-loop stepper motors that communicate to coordinate multiple cutting actions.

Meanwhile, the new Z1 has many similar traits, such as the quick tool changer, but incorporates additional innovations like a built-in camera as the machines continue to evolve.

“[The Carvera] caters more to engineers who operate multi-million-dollar machines and want to replicate that experience at home without breaching workplace policies,” Erdreich explained.

“They desire the same tolerances, auto tool changing, and features they are accustomed to, but in a home environment. It’s also utilized by businesses for their own R&D; they previously relied on outsourcing for initial parts, which could cost thousands of dollars—now, materials for such projects may only cost around $30.

“The Carvera Air primarily serves DIYers and educational purposes, as it provides nearly identical tolerances to the Carvera—the main distinction being the absence of the tool changer, which is not a significant drawback unless engaged in large-scale production.

“Conversely, the Z1 is specifically aimed at those with 3D printers who want to explore subtractive manufacturing. Its capabilities are comparable; it simply operates at a slightly slower pace.”

There is a noticeable age gap among the three machines—the Carvera, being three years old, contrasts with the newly launching Z1, which, despite being 20% less expensive, features advancements like a vice, a vacuum table, a 3D probe, and a camera.

Erdreich mentioned that the company plans to offer upgrade kits for each model, allowing customers to activate features on machines they have previously purchased.

“From a product lifecycle perspective, the Carvera, being three years old, will soon receive another round of attention with the new model.”

Innovative machining solutions

While Makera has built its reputation on the physical machines, it is now enhancing its offerings with software that enables users to design their creations.

At its inception, Makera lacked proprietary software, opting instead to ensure its machines were compatible with popular platforms for generating G Code—the language understood by the machines regarding their tasks.

Now, the company is developing an open-source software suite that users can leverage to design their projects, introducing its own LLM that can interpret descriptions of creations and generate the appropriate G Code.

Additionally, the brand is launching a new platform called Makerables, which functions as a site for sharing files where users can exchange models.

“The new software includes AI generative tools that allow users to upload images and produce 3D models—if you request something like a dog tag, it will generate a model tailored for CNC milling, which can then be sent directly to our new Makera Studio.”

The

Other articles

NASA explains the reason for canceling its first spacewalk in eight months.

NASA has been preparing for two spacewalks at the International Space Station (ISS) over the past few weeks, marking its first in eight months. However, just a few hours prior to the scheduled start of the first walk on Thursday by astronauts Mike Fincke and Zena Cardman, NASA announced that the event was being postponed due to [...]

NASA explains the reason for canceling its first spacewalk in eight months.

NASA has been preparing for two spacewalks at the International Space Station (ISS) over the past few weeks, marking its first in eight months. However, just a few hours prior to the scheduled start of the first walk on Thursday by astronauts Mike Fincke and Zena Cardman, NASA announced that the event was being postponed due to [...]

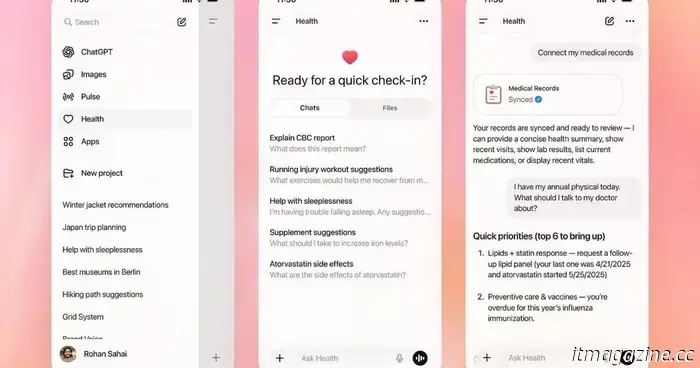

ChatGPT Health aims to serve as your medical AI assistant, but please don't anticipate receiving a diagnosis.

ChatGPT Health is OpenAI's response to the way individuals are currently utilizing AI for medical inquiries, providing selected sources, enhanced guidelines, and more secure health-related answers.

ChatGPT Health aims to serve as your medical AI assistant, but please don't anticipate receiving a diagnosis.

ChatGPT Health is OpenAI's response to the way individuals are currently utilizing AI for medical inquiries, providing selected sources, enhanced guidelines, and more secure health-related answers.

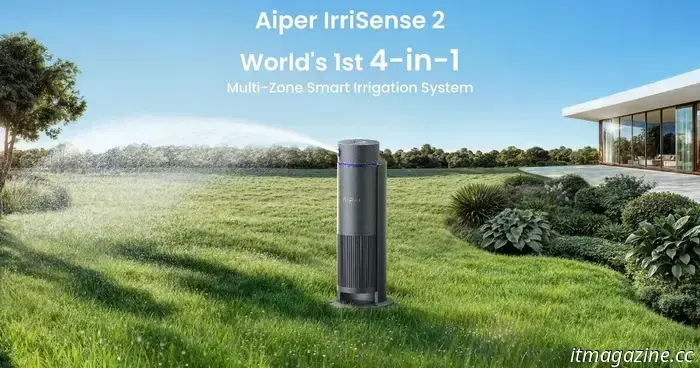

This intelligent device guarantees that you'll always remember to water your garden.

The Aiper IrriSense 2 is an intelligent irrigation system that eliminates the need to worry about your lawn.

This intelligent device guarantees that you'll always remember to water your garden.

The Aiper IrriSense 2 is an intelligent irrigation system that eliminates the need to worry about your lawn.

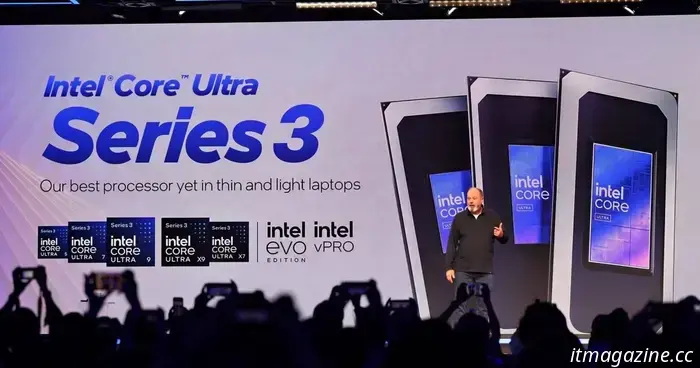

Intel aims to equip your next handheld device with Core G3 processors.

Intel is said to be working on Intel Core G3 handheld processors that utilize Panther Lake, featuring Arc B390 integrated graphics improvements as a key highlight. Here's the potential impact of this development on portable gaming laptops.

Intel aims to equip your next handheld device with Core G3 processors.

Intel is said to be working on Intel Core G3 handheld processors that utilize Panther Lake, featuring Arc B390 integrated graphics improvements as a key highlight. Here's the potential impact of this development on portable gaming laptops.

Digital Trends’ Best Tech of CES 2026 awards: our top selections from the exhibition floor

Here are the 22 top products we encountered at CES 2026.

Digital Trends’ Best Tech of CES 2026 awards: our top selections from the exhibition floor

Here are the 22 top products we encountered at CES 2026.

Forget about 3D printing – these devices can create much more at home.

This article is presented in collaboration with Makera. Some individuals may not be very familiar with CNC machining; they might merely recognize the machines that Makera manufactures and consider them to be smaller versions of those utilized in shop classes during their youth. And they would be correct, [...]