Rostec has started producing a specialized adhesive for electronics.

In the world of high technology, sometimes the most inconspicuous components decide everything. Take glue, for example. When it comes to microchips for military equipment, satellites, or rugged laptops, it turns out a good adhesive must not lose its properties in Arctic cold or searing heat. That is why Rostec has begun serial production of specialized adhesive compounds for the radio-electronic industry.

The development belongs to the Rosel holding, part of the corporation, and is designed to replace foreign analogues that were previously the only option for domestic manufacturers.

The new material has outstanding characteristics:

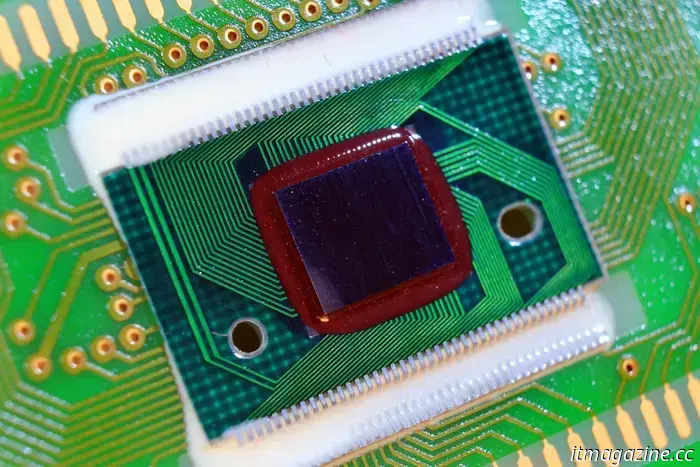

For example, its thermal conductivity is 10.5 W/m·K, comparable to some metals. So while ordinary glue in a microchip merely bonds parts together, this one also works as a mini heatsink, dissipating excess heat.

The newcomer is not afraid of extreme temperatures and does not lose its properties from -60°C to +175°C. Ordinary epoxy resin under such conditions would have long since cracked or flowed.

The product also does not leave voids during application. In microelectronics, the quality of the potting determines whether the equipment will work or end up as scrap.

Such components are used in rugged laptops, radar systems, chassis control devices, and other critically important sectors. The distinctive feature of the adhesive is its ability to ensure stable operation of equipment even under extreme conditions.

Unlike traditional methods of joining components, such as welding or soldering, adhesive bonding does not require high temperatures to cure. This eliminates the risk of deforming sensitive microchip elements and simplifies the manufacturing process.

As Valery Sazonov, general director of CKB RM, noted, the absence of solvents in the composition and the moderate curing temperature allow the adhesive to be used in the manufacture of electronics across different classes. In addition, switching to a domestic material will reduce production costs.

Previously such high-tech adhesives were purchased abroad. But, as is known, in the context of sanctions and other geopolitical "antics" it has become difficult to rely on stable supplies. Now a domestic product has been introduced to the Russian market that not only matches foreign counterparts but may even surpass them in some parameters.

Meanwhile, such "small things" hold enormous possibilities for the entire domestic electronics industry. And if before we depended on foreign supplies even for seemingly minor components like glue, now we can be confident that Russian microchips will not fail at the most critical moment.

So, one could say, Rostec did not just create a new material — it glued together another piece of technological sovereignty. And, apparently, firmly.

Other articles

Rostec has started producing a specialized adhesive for electronics.

In the world of high technology, sometimes the most unassuming components make all the difference. Take glue, for example. When it comes to microchips for military equipment, satellites, or rugged laptops, it turns out that a good adhesive must retain its properties both in Arctic cold and in blistering heat. That's why Rostec has begun mass production of specialized adhesive formulations for the radio‑electronics industry.