A laboratory in Lisbon is transforming deceased bacteria into treats for dogs. Coming soon: Snacks for humans.

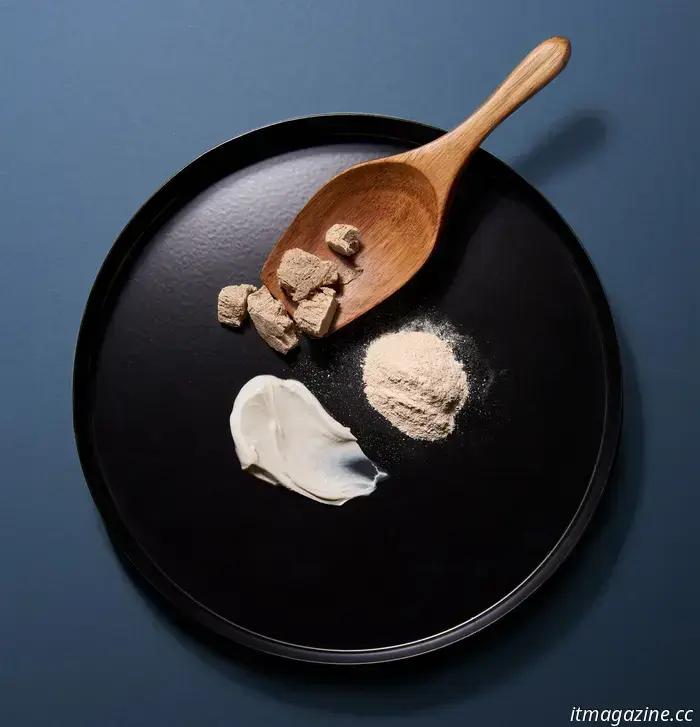

“Microbial protein,” Katelijne Bekers exclaims, gesturing with a vial of beige powder as if it were a magical elixir. Though it doesn’t resemble your standard lunch item, this humble substance could significantly impact the future of food.

Bekers is the co-founder of MicroHarvest, a startup based in Hamburg and Lisbon that transforms agricultural waste into protein powder using microbes—tiny organisms found all around us. This vegan ingredient has already started to be integrated into dog treats, with plans for human snacks like protein bars, shakes, and ice cream to follow if everything goes according to plan.

I visited the company’s pilot plant in Lisbon on a hot summer afternoon last month. It’s located within the Unicorn Factory, a vast industrial area on the eastern side of the city that once produced pasta and cookies for the Portuguese military. Now, instead of carbohydrates for soldiers, it houses fermenting vats of bacteria.

Established in 2022, the Unicorn Factory is home to some of Portugal’s most promising startups. Credit: Unicorn Factory

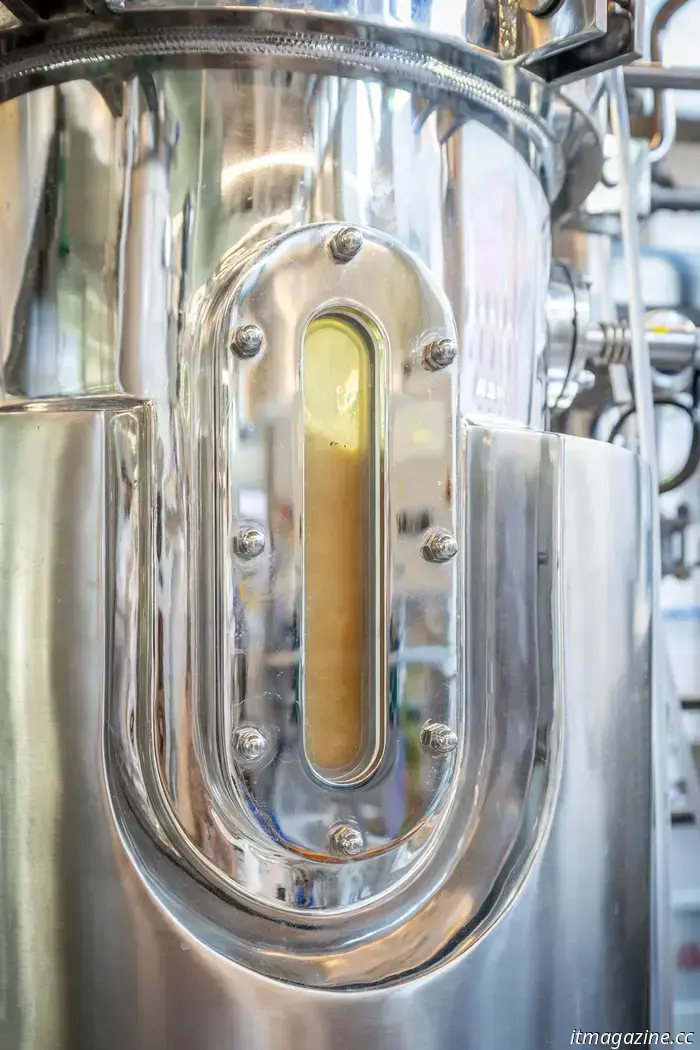

At the heart of the lab stands a large steel fermenter with a small window, allowing glimpses of a thick brown liquid bubbling away inside. Billions of microbes inside are consuming leftover sugars from the agricultural sector and multiplying like microscopic gremlins. Once their task is complete, they are terminated and dried into a protein-rich powder.

“We like to say they’re ‘inactivated,’” Bekers, who hails from the Netherlands, tells TNW with a chuckle. “It sounds nicer.”

The final product resembles light brown flour and has a faint aroma akin to Marmite. It boasts a substantial nutritional profile — approximately 60% raw protein, along with a blend of fiber, amino acids, and other nutrients.

MicroHarvest’s powder enters an already crowded market for alternative proteins — including lab-grown chicken, algae nuggets, pea patties, and mycoprotein steaks. However, Bekers firmly believes that microbes deserve a place on our plates.

“What we’re producing is far more efficient than plant or animal-based proteins,” she asserts. “You don’t require vast areas of land or large amounts of water. Our microbes grow in days, not months or years, and they convert feed into protein with remarkable efficiency.”

A glimpse into the future of fermentation? Credit: MicroHarvest

MicroHarvest’s fermentation process takes under 24 hours — remarkably swift compared to growing soy or raising cattle. It is estimated to reduce land usage by 99% and lower CO2 emissions by over 70% in comparison to beef.

A 2022 study published in Nature indicated that substituting just 20% of global beef consumption with microbial proteins could halve annual deforestation by 2050. Additionally, bioreactors like those used by MicroHarvest could be established almost anywhere with a significant agricultural industry.

Of course, the concept of consuming dried bacteria might raise some eyebrows — or stomachs. But Bekers quickly draws parallels to familiar foods.

“These are akin to the microbes present in yogurt, kimchi, or sauerkraut,” she explains. “Food is a cultural phenomenon, and we understand that. We’re not attempting to replace your steak or convert everyone to veganism. We’re merely adding another protein source to the menu.”

Fermenting the future

MicroHarvest’s protein powder can be incorporated into various foods and is also an effective thickening agent. Credit: MicroHarvest

MicroHarvest stands as one of Europe’s leading producers of microbial protein, yet the landscape is bustling with competition. Startups across the continent and beyond are innovating with various microbes and feedstocks — from Germany’s Formo producing alternative dairy to the UK’s Enough converting fungi into meat.

At the same time, corporate giants like Nestlé and Unilever are exploring the sector through collaborations and pilot projects.

Globally, nearly $1 billion (€874 million) flowed into fermentation-based alt-protein startups last year, according to Dealroom data. Europe attracted almost half of that, with 2024 projected to be the sector's highest funding year ever on the continent.

In conjunction, the EU introduced a new €350 million funding strategy in July aimed at accelerating the scaling of fermentation technology, as the continent strives to address its deep-seated reliance on meat.

Even substituting a portion of our protein intake with a fermented alternative is a compelling idea. It could considerably lessen the land and water required for farming while drastically cutting carbon emissions. However, the transition is not without challenges.

From pets to people

Replacing steak with microbes is not as simple as just building additional bioreactors. Fermented proteins currently face high production costs and the hurdle of convincing skeptical consumers, whose food choices are often influenced by cultural factors.

Moreover, there’s the issue of regulatory hurdles. It remains uncertain when — or if — MicroHarvest will receive approval for human consumption. The prolonged approval process for alt-protein products has hindered other startups in the sector. For instance,

A laboratory in Lisbon is transforming deceased bacteria into treats for dogs. Coming soon: Snacks for humans.

Dead bacteria for dinner? We visited MicroHarvest's microbial protein lab to explore the future of food.